DIY Timber Floating Shelf Coat Rack

Step by step instructions to easily make this floating shelf coat rack.

G'day guys, another Friday / another DIY!

Thank you everyone for tuning in, we are loving bringing these woodworking projects to you each week - thanks for all of your feedback recently and sharing your DIY ideas with us! We've made a list and will work our way through them!

This week we decided to create a simple timber floating shelf coat rack. This is a great woodworking project for an entranceway, kitchen, bathroom or kids room!

Enjoy!

AL + IMO

“This is a great project for any room in your house. ”

TOOLS

TAPE MEASURE

PENCIL

DRILL

NAIL GUN OR HAMMER

SANDER OR SANDPAPER

SANDPAPER

DROP SAW

NAIL PUNCH

PROTECTIVE GEAR

SAFETY GLASSES

EAR PROTECTION

TIMBER

For this project we used 15mm Blackbutt hardwood flooring and 25mm Victorian Ash hardwood dowel.

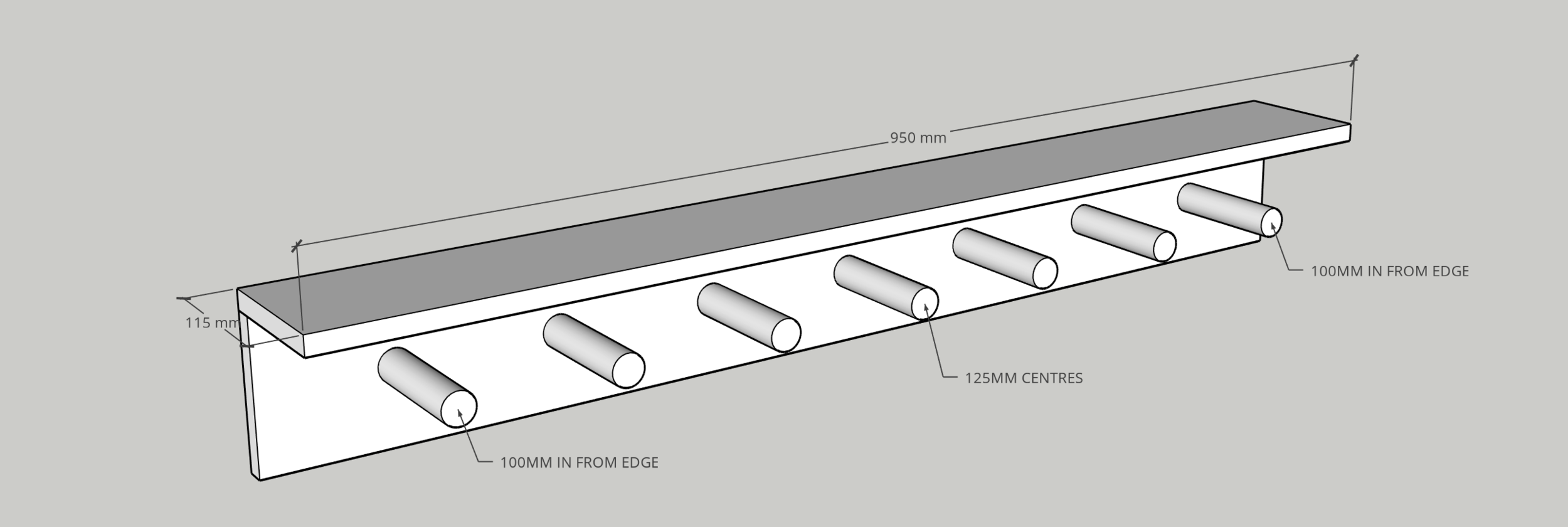

BACKBOARD & SHELF - 950mmL x 115mmW x 15mm

DOWEL PEGS - 7 x 25mm Dowel x 100mmL

HARDWARE

NAILS

SCREWS

MATERIALS

HARD WAX OIL

WOOD PUTTY OF A SIMILAR COLOUR (OPTIONAL)

Step 1.

Because I used some scrap floorboards I ripped my edges down and plained them smooth.

Step 2.

I measured and cut my shelf and backboard to length 950mm. I then worked out how many dowel pegs I wanted for my shelf - I decided on 7.

Step 3.

To work out the length of my dowel pegs I measured the width of my top shelf timber and minused the thickness of the backboard so the pegs were even with my top shelf.

I made a mark on my drop saw and cut each dowel to length. 100mm

Step 4.

I sanded my shelf and backboard smooth with my orbital sander and then using hand sandpaper sanded my dowel - rounding off the outside edge of the dowel only.

Step 5.

I measured and marked my dowel spacings and with a set square and marked my centres. I pre-drilled on the front side of my backboard and in the centre of my dowels - making sure to drill straight.

100mm in from each end and then 125mm spacings.

Step 6.

I flipped over my backboard and using my spade-bit I drilled counter-sink holes where my pre-drilling holes had come through.

Step 7.

To attach the dowel I smeared a small amount of glue on the end. Using my drill I screwed through my backboard and as the screw poked through I lined my dowel and screwed it tight. I repeated this with the remaining dowels, making sure the end grain was vertical as I wanted all of them to match.

Step 8.

To attach the top shelf I glued, clamped and nailed it into place. I left it to dry with the clamps holding it in position and once dry I punched the nails in with my nail punch. I then gave the top and back a light sand.

Step 9.

I sealed our shelf with a hard wax oil that brings out the natural feature in the timber, once dry I filled the nail holes with similar coloured putty, gave it a light sand and added a second coat for a silky smooth finish.

Step 10.

Finally I attached the shelf to or wall, making sure to screw into the studs behind so it has a sturdy fixing and ensuring it was level

More Home Styling Tips

HEY! WE’RE AL + IMO

We’re a husband and wife duo, building our dream life one DIY project at a time. We are proudly self-taught, furniture-makers, business owners, designers and stylists.

DIY RUNS IN OUR DNA

We firmly believe what you learn should be shared which is why we created our Journal. A place where you can learn new skills and be inspired by other creatives.

Top Categories

ON THE JOURNAL

How we built a handmade dollhouse using upcycled furniture, miniature furniture, and creative DIY details, inspired by family, play, and imagination.

We installed four VELUX FS Fixed Skylights (780 x 1180mm) into our pitched Colorbond roof to replace LED panels and bring in natural light. See how we did it using custom The Skylight Warehouse custom flashing kits.

We recently bought an artwork from Bluethumb and i’ve curated a collection of my favourite finds. Plus, get 5% off your purchase with code alimo5. Discover original art by Aussie artists online.

If you’re building your own little library or looking for the best books for babies and toddlers, we’ve pulled together a list of our all-time favourites. These are the ones we’ve read on repeat - the ones that always end up back in little hands.

After years of searching for the perfect doona, we finally found it—Bonny Doona. Soft, breathable, and made for all seasons, this is the ultimate bedding upgrade for a restful sleep.

Discover how to style your home with art and collected objects in a way that feels personal, curated, and cohesive. Follow these five simple tips to create a space that tells your unique story.

Check out how we turned an old cubbyhouse we found on Facebook Marketplace into a cafe to inspire imaginative play!

See how we transformed $100 Facebook Marketplace dining chairs into timeless hardwood beauties. A sustainable upcycling project that saves furniture from landfill while creating unique, durable pieces.

Looking for a fresh, vibrant meal that’s quick to throw together and always a winner? This Vietnamese noodle salad is on high rotation in our house – perfect for lunch or dinner. Packed with crunchy veggies, fresh herbs and a zesty dressing, it’s light, satisfying, and full of flavour. Whether you’re feeding the family or hosting friends, it’s sure to hit the spot!

This year, our raised veggie garden has truly become one of our favourite spaces at the Good Day House. Designed by the talented Simon Taylor Landscape Design, this little patch of paradise has been a joy to nurture and watch thrive. It’s not just a garden—it’s become a place of connection, learning, and delicious rewards!

Imogen Gilchrist is a creative director, Squarespace website designer and social media strategist who loves good design & good people.